In this post I share some illustrations and extracts from a rare eighteenth century book about flax and hemp cultivation, processing and weaving.

The book’s full title is: A Treatise concerning the Manner of Fallowing of Ground, Raising of Grass-Seeds, and Training of Lint and Hemp, for the increase and improvement of Linnen-Manufactories in Scotland, by the Honourable Society for Improving in the Knowledge of Agriculture. It was published in Edinburgh in 1724 and is attributed to William Mackintosh. As far as I know it is the earliest publication in English about the technicalites of linen weaving. There is a leather-boud copy in Senate House Library, University of London. The title “Farming in Scotland” is embossed on the spine.

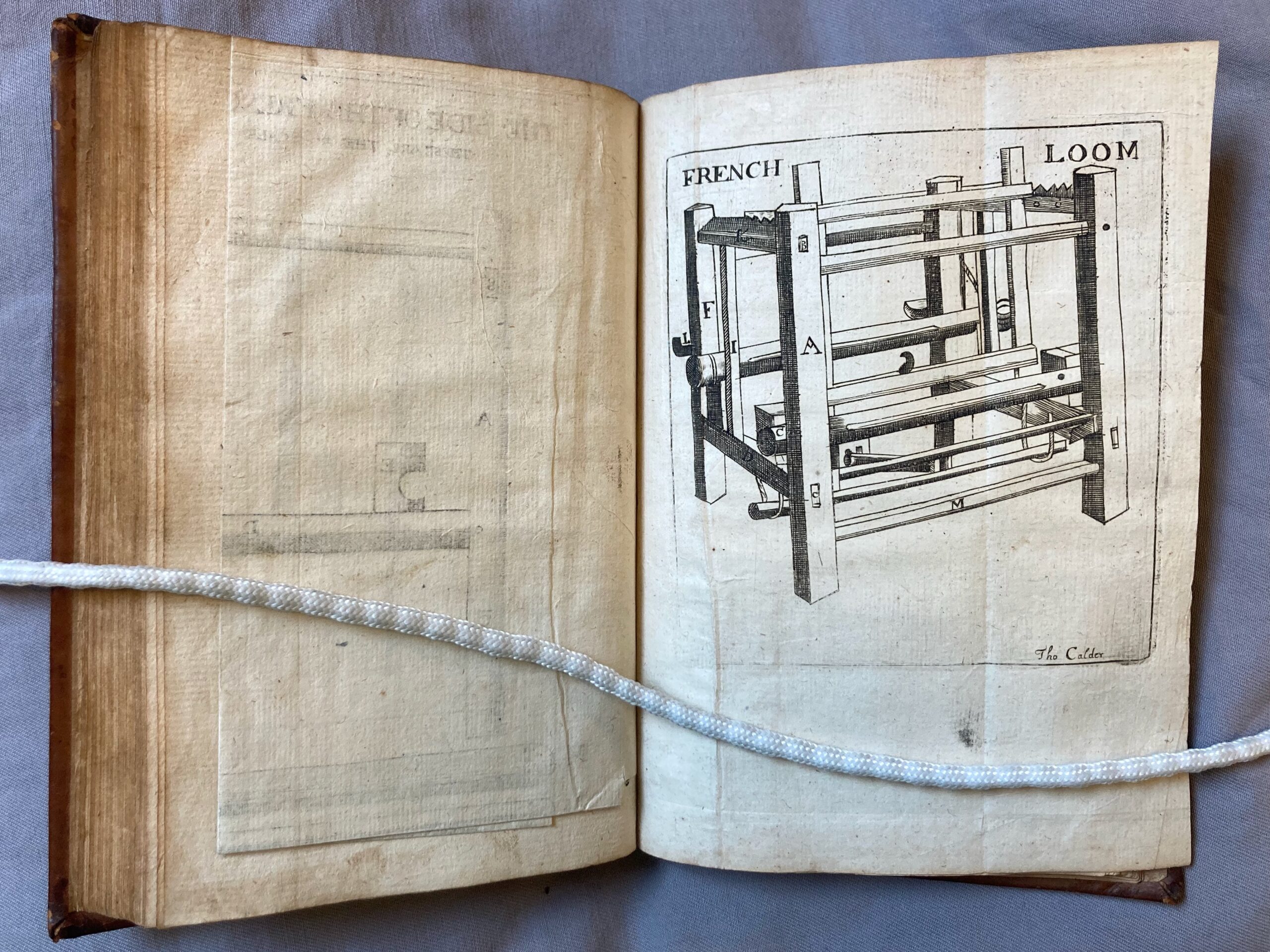

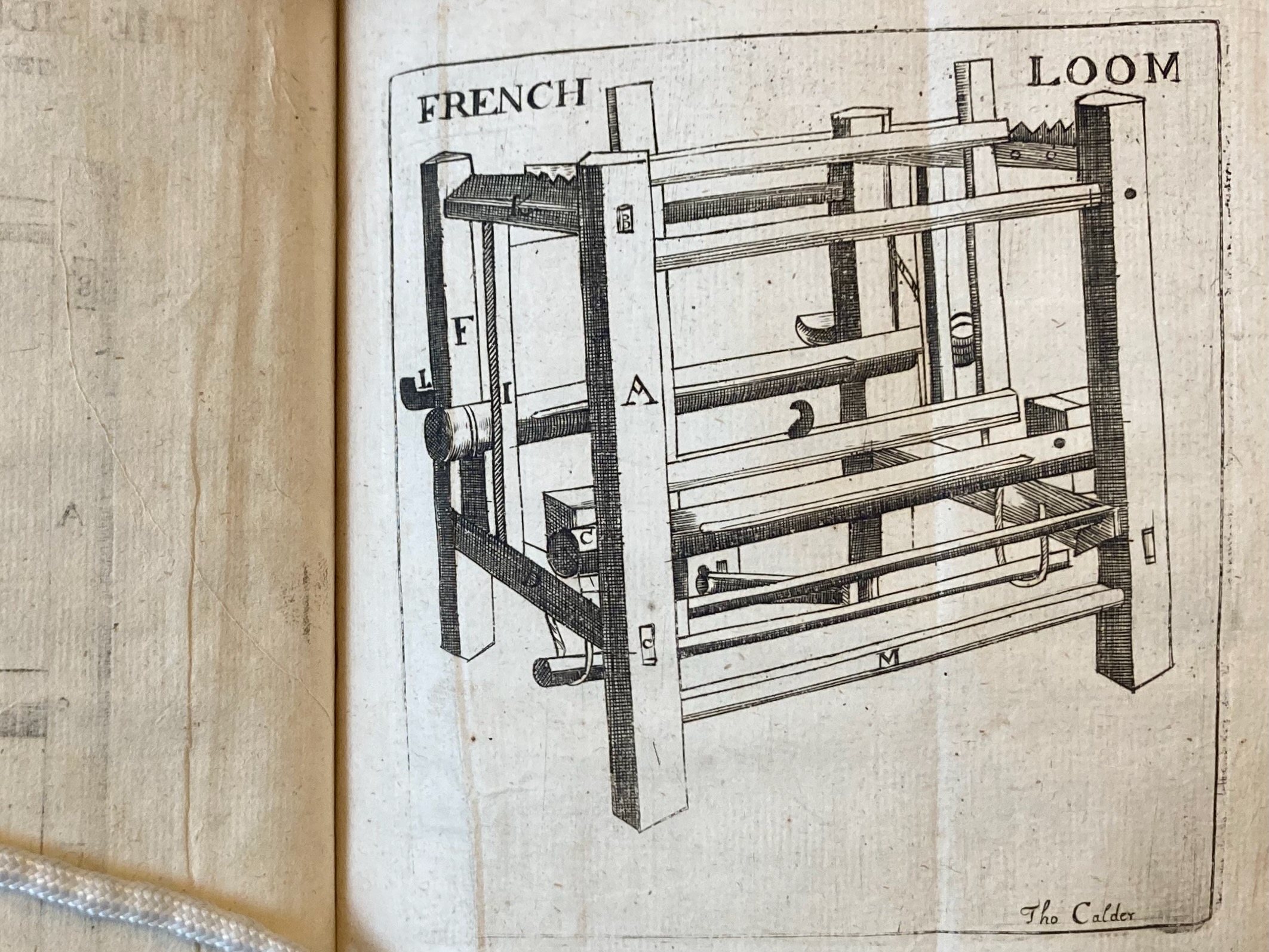

The book contains seven foldout plates with illustrations of French, Dutch and ‘Estille’ Looms, and flax dressing tools. I include photographs of the loom illustrations along with extracts dealing with their dimensions. I also inlcude extracts from Chap. VII: Concerning Weaving of Linnen-Cloth in Imitation of the Foreign Linnen.

Photographs courtesy of Senate House Library, University of London.

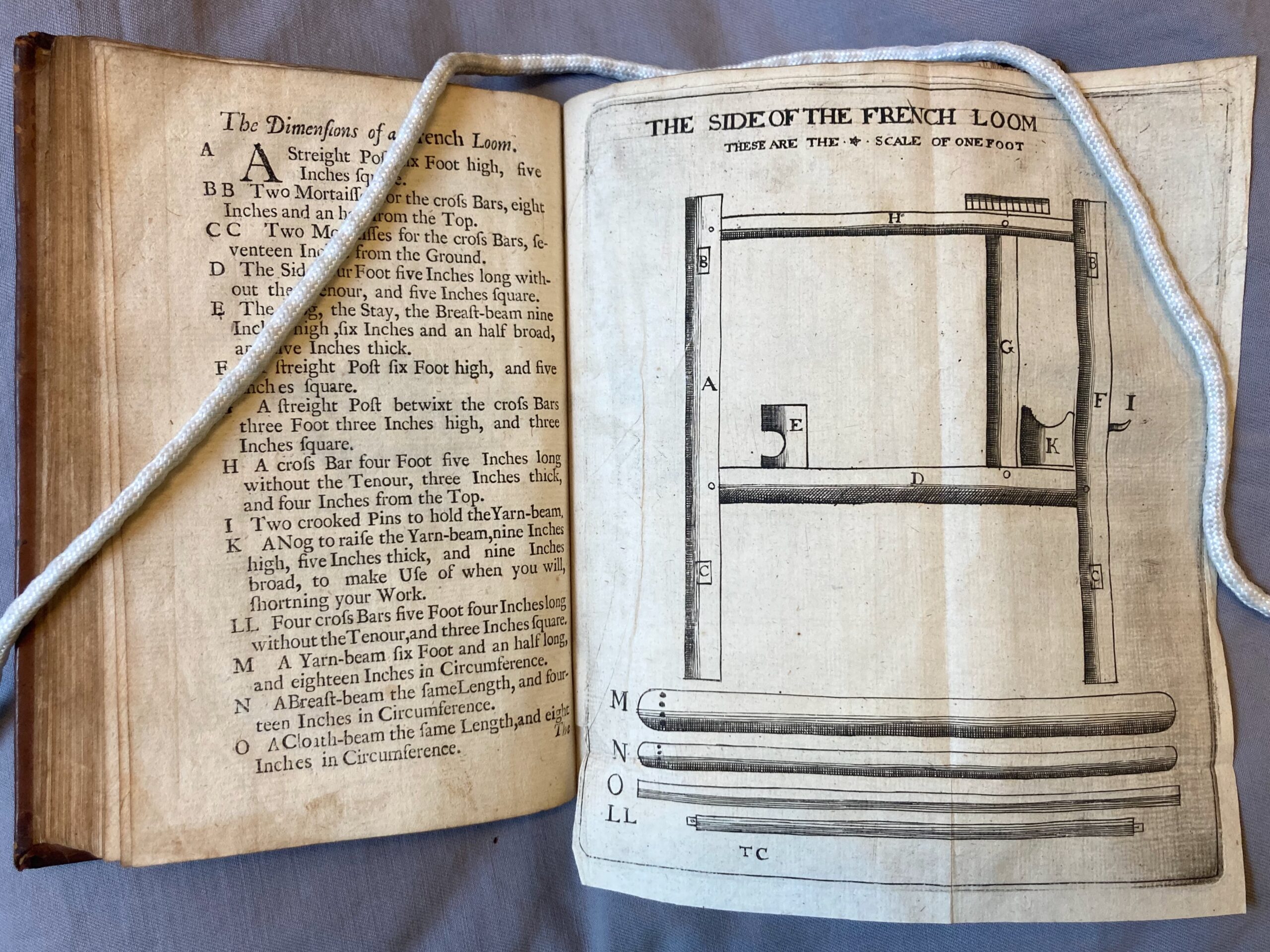

The French Loom

The Dimensions of a French Loom

A A Streight Post six Foot high, five Inches square.

BB Two Mortaisses for the cross Bars, eight Inches and an half from the top.

CC Two Mortaisses for the cross Bars, seventeen Inches from the ground.

D The Side four Foot five Inches long without the Tenour, and five Inches square.

E The Nog, the Stay, the Breast -beam nine Inches high, six Inches and an half broad, and five Inches thick.

F A streight Post six Foot high, and five Inches square.

G A streight post betwixt the cross Bars three Foot three Inches high, and three Inches square.

H A cross Bar four Foot five Inches long without the Tenour, three Inches thick, and four Inches from the Top.

I Two crooked Pins to hold the Yarn-beam.

K A Nog to raise the Yarn-beam, nine Inches high five Inches thick, and nine Inches broad, to make Use of when you will, shortening your Work.

LL Four cross Bars five Foot four Inches long without the Tenour, and three Inches square.

M A Yarn-beam six Foot and an half long, and eighteen Inches in Circumference.

N A Breast-beam the same Length and fourteen Inches in Circumference

O A Cloth-beam the same Length and eight Inches in Circumference.

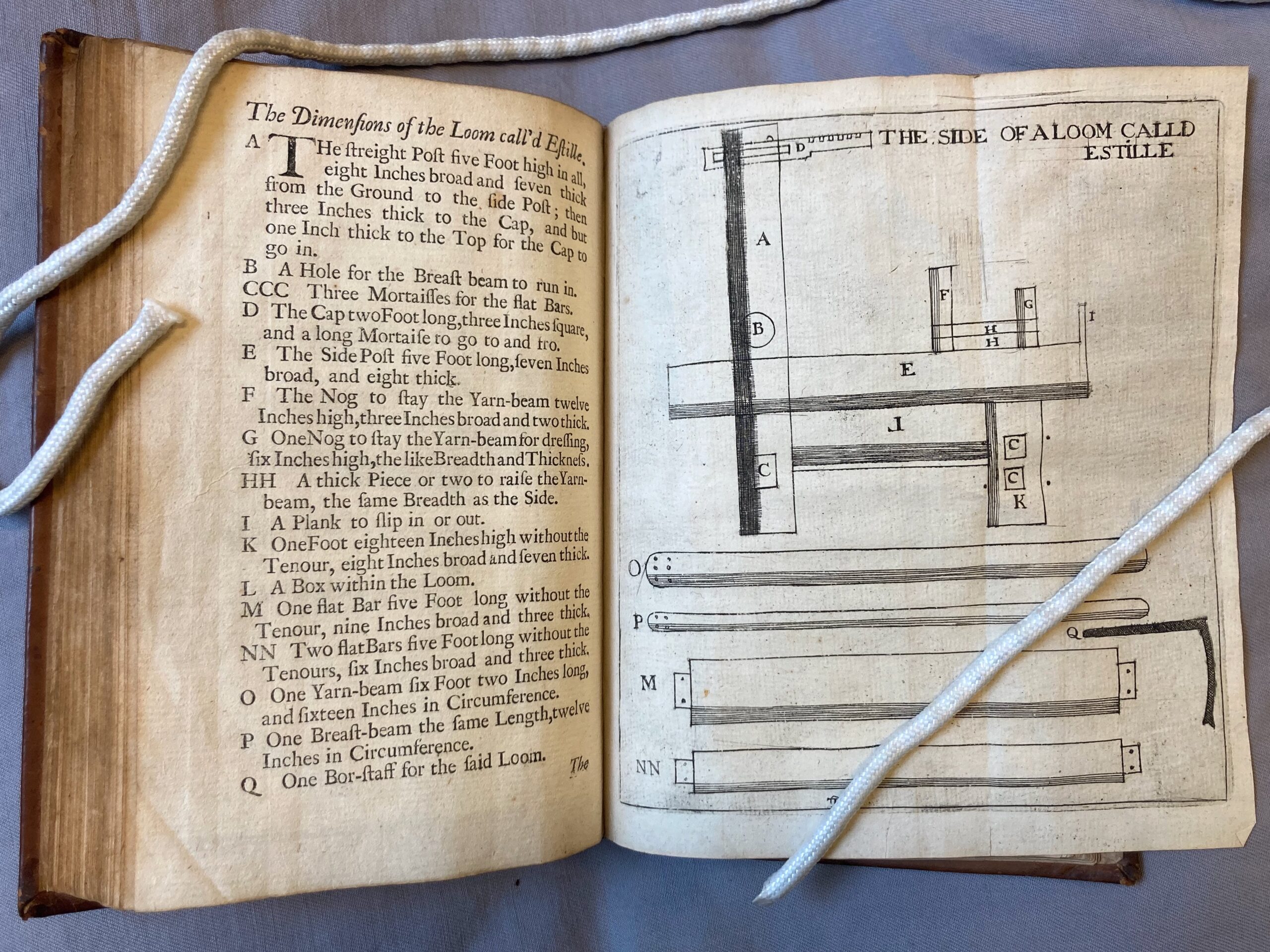

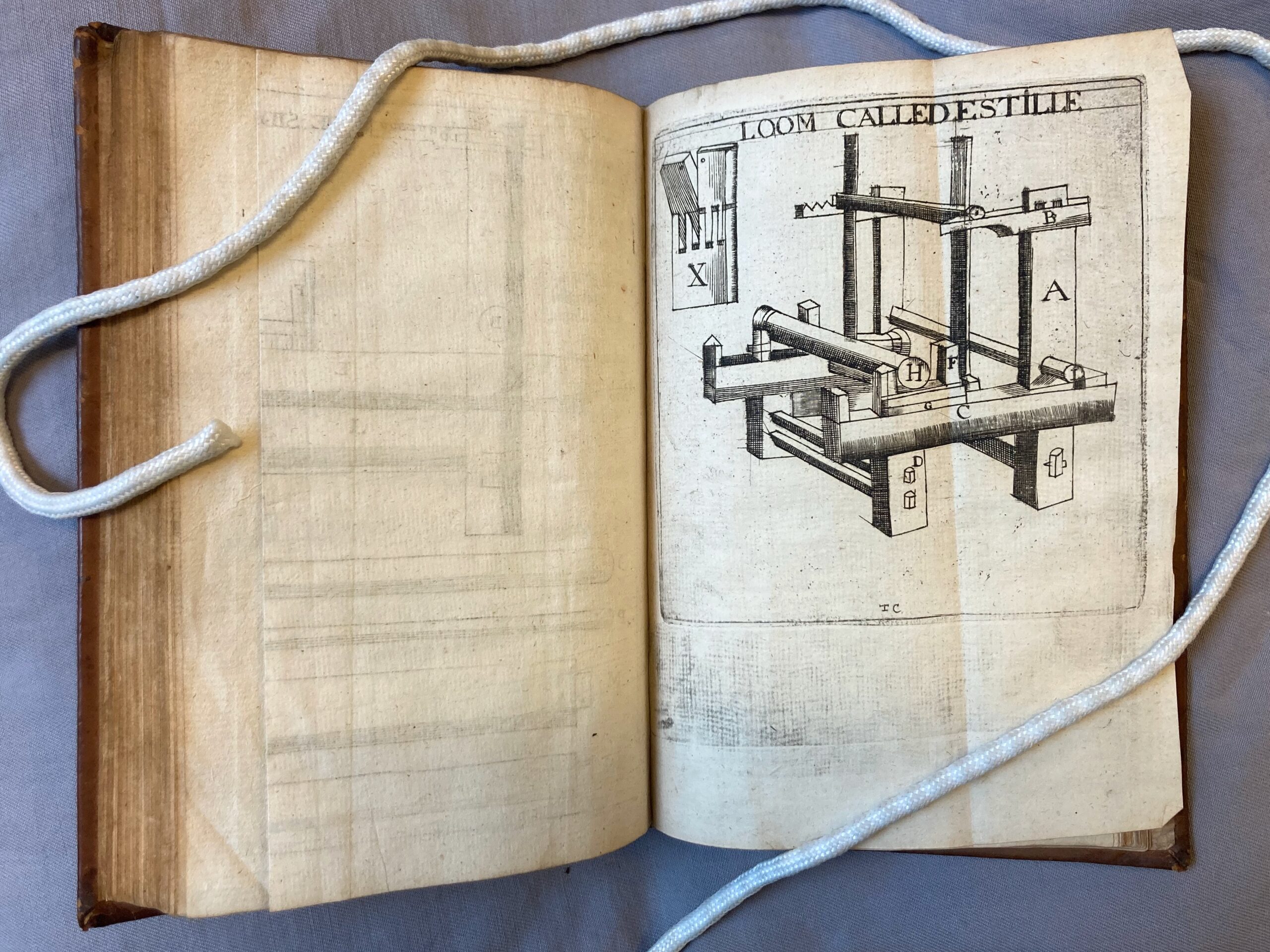

The Loom Called Estille

The Dimensions of the Loom call’d Estille.

A The streight Post five foot high in all, eight inches broad and seven thick from the Ground to the side Post; Then three Inches thick to the Cap, and but one Inch thick to the top for the Cap to go in.

B A Hole for the Breast-beam to run in.

CCC Mortaisses for the flat Bars.

D The Cap two Foot long, three Inches square, and a long Mortaise to go to and fro.

E The side Post five foot long, seven inches broad, and eight thick.

F The Nog to stay the Yarn-beam twelve Inches high, three Inches broad and two thick.

G One Nog to stay the Yarn-beam for dressing, five Inches high, the like Breadth and Thickness.

HH A thick Piece or two to raise the Yarn-beam, the same Breadth as the Side.

I A Plank to slip in or out.

K One Foot eighteen Inches high without the Tenour, eight Inches broad and seven thick.

L A Box within the Loom.

M One flat Bar five Foot long without the Tenour, nine Inches broad and three thick.

NN Two flat Bars five Foot long without the Tenours six Inches broad and three thick.

0 One Yarn-beam six Foot two Inches long, and sixteen Inches in Circumference.

P One Breast-beam the same Length twelve Inches in Circumference.

Q One Bor-staff for the said Loom.

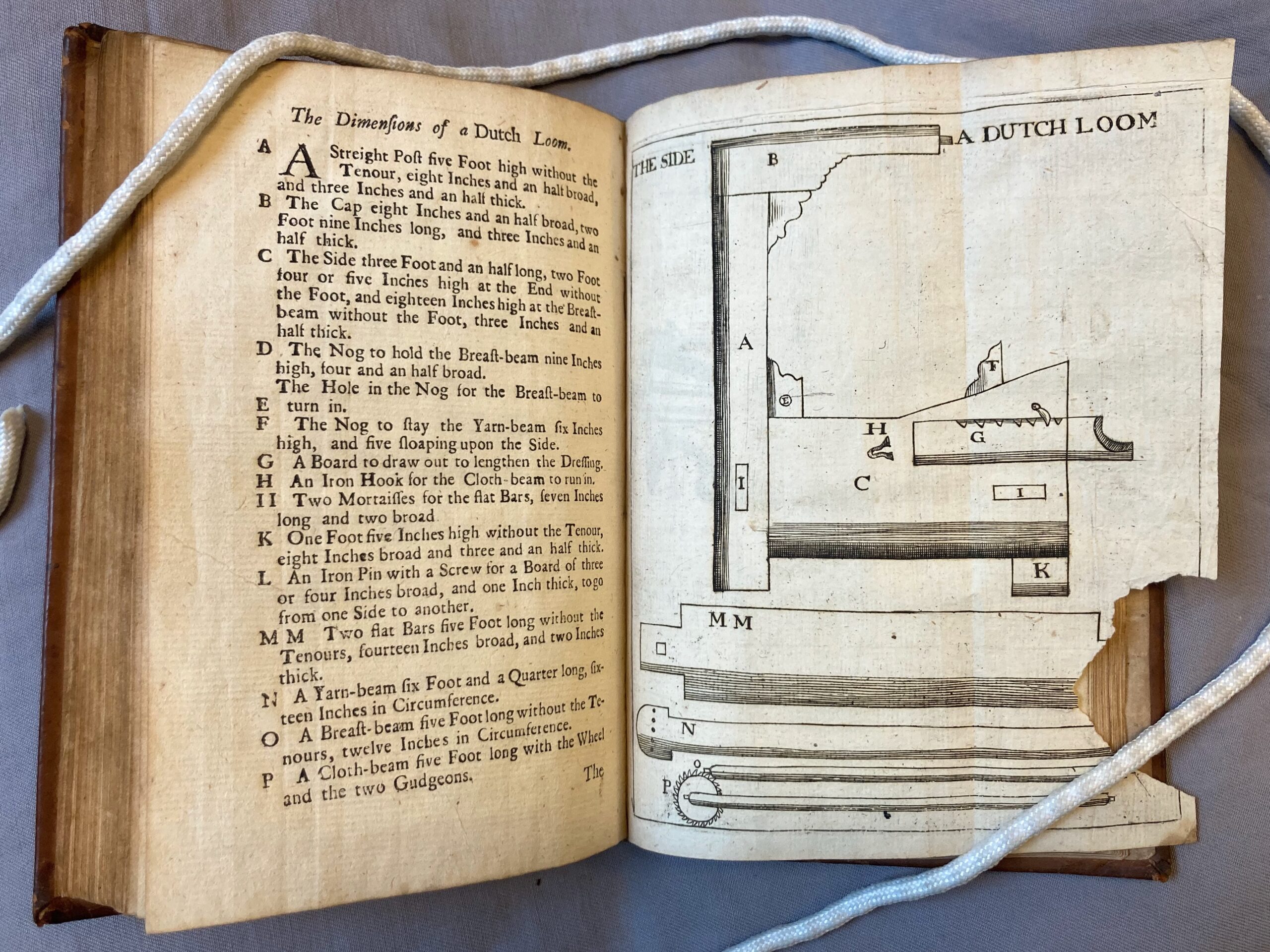

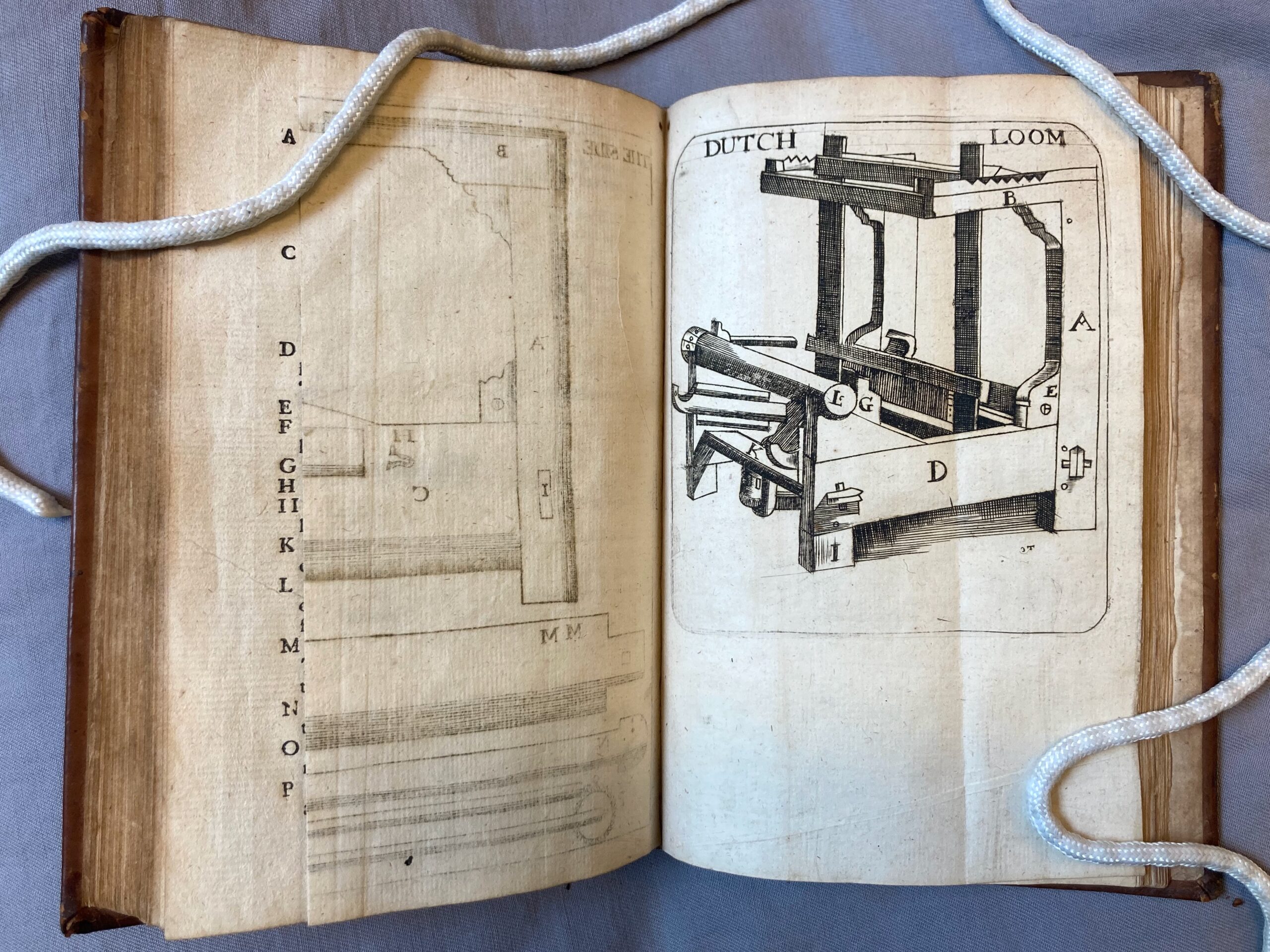

The Dutch Loom

The Dimensions of a Dutch loom.

A A streight Post five Foot high without the Tenour, eight Inches and an half broad, and three Inches and an half thick.

B The Cap eight Inches and an half broad, two Foot nine Inches long, and three Inches and an half thick.

C The Side three Foot and an half long, two Foot four or five Inches high at the End without the Foot, and eighteen Inches high at the Breast-beam without the Foot, three Inches and an half thick.

D The Nog to hold the Breast-beam nine Inches high, four and an half broad.

E The Hole in the Nog for the Breast-beam to turn in.

F The Nog to stay the Yarn-beam six Inches high, and five sloaping upon the side.

G A Board to draw out to lengthen the Dressing.

H An Iron Hook for the Cloth-beam to run in.

II Two Mortaisses for the flat Bars, seven Inches long and two Foot broad.

K One Foot five Inches high without the Tenour eight Inches broad and three and an half thick.

L An Iron Pin with a Screw for a Board of three or four Inches broad, and one Inch thick, to go from one Side to another.

MM Two flat Bars five Foot long without the Tenours, fourteen Inches broad, and two Inches thick.

N A Yarn-beam six Foot and a Quarter long, sixteen inches in Circumference.

O A Breast-beam five Foot long without the Tenour, twelve Inches in Circumference.

P A Cloth-beam five Foot long with the Wheel and two Gudgeons.

Extracts from Chap. VII: Concerning Weaving of Linnen-Cloth in Imitation of the Foreign Linnen

Whereas a good Artist can never make commendable Goods with improper Tools, he that will weave good Linnen Cloth must suit his Looms to the Nature of the Cloth which he designs to make: As for Instance, he that would make a strong substantial Holland, can never do it with one of our Estilles or Flanders Looms: Or on the other Hand, he that would make a Cambrick, Baptist or Lawn, or French Holland, shall never make them on Dutch Looms: Therefore in Holland they have one Sort of Looms; In France and Flanders, where they make your plain, or spotted or strip’d Cambricks they have another Sort of Looms, which they call Estilles: in Normandy and Brittany in France they use also a third Sort of Looms: All these employ the Industry in different Sorts of Linnen Cloth, and have fined and refined thereon for many Hundreds of Years… The Structure of the Looms is so essential to your Work, that you will be convinced thereof by one single Instance.

2dly, suppose you were to weave the Linnen Cloth (commonly called Holland) in one of the Looms of this Kingdom; The Beams are set so far asunder, and the Loom itself so slight, (which can’t be otherwise, if you design therein ever to weave Woollen) that you can never make your Cloth firm and substantial; For the nearness of the two Beams in the Dutch Looms, makes the Warp lighter and firmer, and the force of the Leath is much greater on your Weft and strikes it closer with one Blow, than you could possibly do with many Strokes of your Leath in your ommon Loom. Wooden yarn or Worsted, can by no means bear such rough and hard Usage: therefore it is impossible to use one and the same Loom to both the Materials with good Success. But further, your Dutch Looms are made with a much greater Quantity of Timber than your common Looms of the Country are; which makes them firm, and unapt to shake or yield with the Force of your Work: whereas your Looms are made slight on Purpose, for the soft and tender Nature of your Woollen Materials.

3dly, The Dutch looms, as I have already observed, are proper for Holland Cloth, but no way proper for your fine Baptists, your French Hollands, your Cambricks, &c. each of which is made-up of finer Yarn than Holland Cloth is; therefore the Estilles are found by Experience to work such fine Yarn better.

4thly, there is yet a third Sort of Loom which is used in Normandy and Brittany in France, which differs in its Structure from that of Holland, because the Cloths they make in those Provinces are never fine: Such Differences as there is in their Looms I will acquaint my Reader withal, and make him best comprehend by the help of the Models engraved at the end of this Book, and the Notes thereon, to which I refer him.

5thly, your next care is to make choice of your Reeds, to the Ends that the Teeth be even, and not too thick; therefore good Reed-makers ought to be encourag’d. It is impossible to make a good Cloth in an unequal and uneven Reed; Neither can the best Workmen in the World make a good Cloth without good Geers which are but badly made in this Kingdom: the Geers generally used in Ireland, are made of over-coarse Thread for weaving of extreme fine Yarn. Coarse Geers are stiff and over-labours your Yarn that runs between the Threads your Geers are made of: it is much better to have Geers that are too fine than two coarse; For the Cloth will last longer by so much as you save and keep your Yarn from breaking and consequently recommend your goods to the Buyers; And you will save your selves much Labour and Time, which would be taken up in Knoting your Warp at every Turn.

6thly, the way of dressing the Yarn in the Loom while it is weaving, is extreamly bad in Ireland; For they make a Stuff of Water and Meal, without Judgement, wherewith they stiffen their Warp; now in France and Flanders &c. they are extreamly curious in the making that Stuff wherewith they dress their Warp; I have therefore given them here the Way of making of it. They must take as much Wheat-flower, and mingle it with cold Water, as will make the Water as thick as Past; this they must boil in the Fire for two Hours at the least, taking Care all that Time to keep it stirring, that it does not burn: If it becomes too thick or too thin, they may help it by adding thereto more water or more flower as occasion is; but then they must (after such addition) boil it at least half an Hour: when it has boiled sufficiently, pour it into a clean Earthen Vessel; where you ought to let it stand till cold: When it is cold, you may make a Hole therein sufficient for you to put some part of your old four dressing Stuff, thereby to leaven the rest, which will set it a Working: When it has fermented for five or six Days, or more, then incorporate the whole together, and use it as you have Occasion. Note, that the older and staler your dressing Stuff is, it is so much the better; wherefore you would always to have a quantity before-hand of it.

8thly, your Weft ought to be always somewhat finer than your Warp. Let the Weaver hold his foot firmly and strongly on his Treadles whilst he weaves, and likewise be careful each Time he throws the Shuttle, that he draws the Thread straight and light to the Cloth he weaves before he strikes with the Leath, or removes his Feet: this will spare him a great deal of Yarn in his Weft, and make his Cloth firm and lasting. There’s but one Thing more that is requisite to be spoken of in reference to the weaving Part of fine Linnen, that at present occurs to my Memory; which is that each Weaver in this Kingdom, who designs to follow that way of Trade, ought to have a Cellar (or some such Place) under Ground to work in; for it is impossible for any man (were he the best Artist in the world) to weave fine Linnen Yarn, unless it be in a close Place; but that the Weather shall affect such Yarn, and cause it to break and snap every Moment.