‘Truly an old craft standing by itself, alone in this England of ours.‘

This post is a transcript of a newspaper article about the linen industry in North & South Lopham, Norfolk, first published in the East Anglian Daily Times on 23rd January 1894. A reprinted version of the article is preserved in the Rita & Percy Beales archive at the Crafts Study Centre, University of the Creative Arts, Farnham.

Transcript:

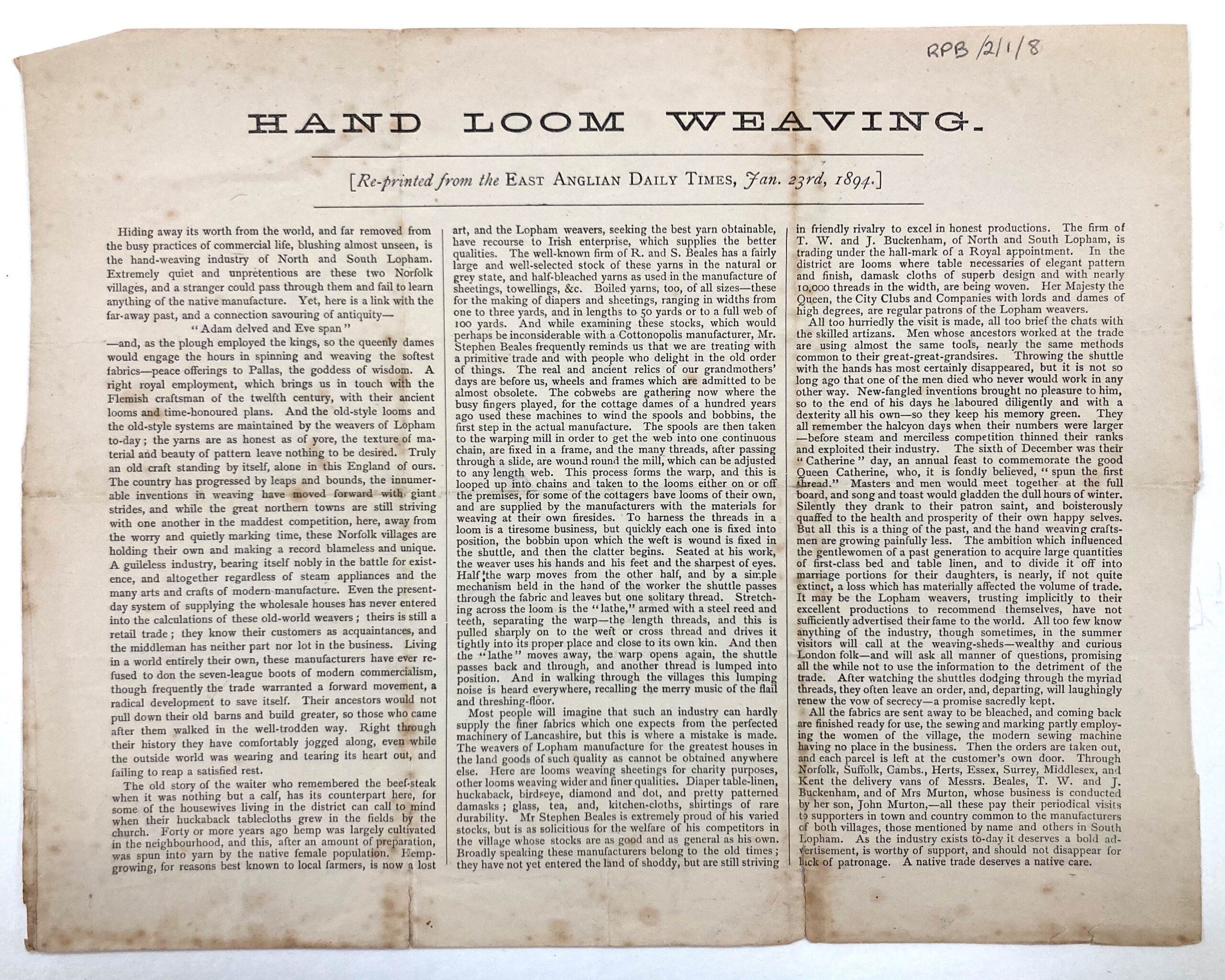

“Hiding away its worth from the world, and far removed from the busy practices of commercial life, blushing almost unseen, is the hand-weaving industry of North and South Lopham. Extremely quiet and unpretentious are these two Norfolk villages, and a stranger could pass through them and fail to learn anything of the native manufacture. Yet here is a link with the far-away past, and a connection savouring of antiquity –

“Adam delved and Eve span”

– and, as the plough employed the kings, so the queenly dames would engage the hours in spinning and weaving the softest fabrics – peace offerings to Pallas, the goddess of wisdom. A right royal employment, which brings us in touch with the Flemish Craftsmen of the 12th century, with their ancient looms and time-honoured plans. And the old-style looms and the old-style systems are maintained by the weavers of Lopham today; the yarns are as honest as of yore, the texture of material and beauty of pattern leave nothing to be desired. Truly an old craft standing by itself, alone in this England of ours. The country has progressed by leaps and bounds, the innumerable inventions in weaving have moved forward with giant strides and while the great northern towns are still striving with one another in the maddest competition, here, away from the worry and quietly marking time, these Norfolk villages are holding their own and making a record blameless and unique. A guileless industry, bearing itself nobly in the battle for existence and altogether regardless of steam appliances and the many arts and crafts of modern manufacture. Even the present day system of supplying the wholesale houses has never entered into the calculations of these old-world weavers; theirs is still a retail trade; they know their customers as acquaintances and the middleman has neither part nor lot in this business. Living in a world entirely their own, these manufacturers have ever refused to don the seven league boots of modern commercialism, though frequently the trade warranted a forward movement, a radical development to save itself. Their ancestors would not pull down their old barns and build greater, so those who came after them walked in the well trodden way. Right through their history they have comfort ubly jogged along, even while the outside world was wearing and tearing its heart out and failing to reap a satisfied rest.

The old story of the waiter who remembered the beef-steak when it was nothing but a calf, has its counterpart here, for some of the housewives living in the district can call to mind when their huckaback tablecloths grew in the fields by the church. Forty or more years ago hemp was largely cultivated in the neighbourhood, and this, after an amount of preparation, was spun into yarn by the native female population. Hemp-growing, for reasons best known to local farmers, is now a lost art, and the Lopham weavers, seeking the best yarn obtainable, have recourse to Irish enterprise, which supplies the better qualities. The well-known firm of R. & S. Beales has a fairly large and well selected stock of these yarns in the natural or grey state, and half bleached yarns as used in the manufacture of sheetings, towellings, &c. Boiled yarns, too, of all sizes – these for the making of diapers and sheetings, ranging in widths from one to three yards, and in lengths to 50 yards or to a full web of 100 yards. And while examining these stocks, which would perhaps be inconsiderable with a Cottonopolis manufacturer, Mr Steven Beales frequently reminds us that we are treating with a primitive trade and with people who delight in the old order of things. The real and ancient relics of our grandmothers’ days are before us, wheels and frames which are admitted to be almost obsolete. The cobwebs are gathering now where the busy fingers played, for the cottage dames of a hundred years ago used these machines to wind the spools and bobbins, the first step in the actual manufacture. The spools are then taken to the warping mill in order to get the web into one continuous chain, are fixed in a frame, and the many threads, after passing through a slide, are wound round the mill, which can be adjusted to any length web. This process forms the warp, and this is looped up into chains and taken to the looms either on or off the premises, for some of the cottages have looms of their own, and are supplied by the manufacturers with the materials for weaving at their own firesides. To harness the threads in a loom is a tiresome business, but quickly each one is fixed into position, the bobbin upon which the weft is wound is fixed in the shuttle, and then the clatter begins. Seated at his work, the weaver uses his hands and his feet and the sharpest of eyes. Half the warp moves from the other half, and by a simple mechanism held in the hand of the worker the shuttle passes through the fabric and leaves but one solitary thread. Stretching across the loom is the “lathe”, armed with a steel reed and teeth separating the warp – the length threads, and this is pulled sharply onto the weft or cross thread and drives it tightly into its proper place and close to its own kin. And then the “lathe” moves away, the warp opens again, the shuttle passes back and through, and another thread is lumped into position. And in walking through the villages this lumping noise is heard everywhere, recalling the merry music of the flail and threshing-floor.

Most people will imagine that such an industry can hardly supply the finer fabrics which one expects from the perfected machinery of Lancashire, but this is where a mistake is made. The weavers of Lopham manufacture for the greatest houses in the land goods of such quality as cannot be obtained anywhere else. Here are looms weaving sheetings for charity purposes, other looms weaving wider and finer qualities. Diaper table-linen, huckaback, birdseye, diamond and dot, and pretty patterned damasks; glass, tea, and, kitchen-cloths, shirtings of rare durability. Mr Stephen Beales is extremely proud of his varied stocks, but is as solicitous for the welfare of his competitors in the village whose stocks are as good and as general as his own. Broadly speaking these manufacturers belonged to the old times; they have not yet entered the land of shoddy, but are still striving in a friendly rivalry to excel in honest productions. The firm of T. W. and J. Buckenham, of North and South Lopham, is trading under the hall-mark of a Royal appointment. In the district are looms where table necessaries of elegant pattern and finish, damask cloths of superb design and with nearly 10,000 threads in the width are being woven. Her Majesty the Queen, the City Clubs and Companies with lords and dames of high degrees, are regularly patrons of the Lopham weavers.

All too hurriedly the visit is made, all too brief the chats with the skilled artizans. Men whose ancestors worked at the trade are using almost the same tools, nearly the same methods common to their great-great-grandsires. Throwing the shuttle with the hands has most certainly disappeared, but it is not so long ago that one of the men died who never would work in any other way. New-fangled inventions brought no pleasure to him, so to the end of his days he laboured diligently and with a dexterity all his own – so they keep his memory green. They all remember the halcyon days when their numbers were larger – before steam and merciless competition thinned their ranks and exploited their industry. The sixth of December was their “Catherine” day, an annual feast to commemorate the good Queen Catherine, who, it is fondly believed, “spun the first thread”. Masters and men would meet together at the full board, and song and toast would gladden the dull hours of winter. Silently they drank to their patron saint, and boisterously quaffed to the health and prosperity of their own happy selves. But all this is a thing of the past, and the hand-weaving craftsmen are growing painfully less. The ambition which influenced the gentlewomen of a past generation to require large quantities of first-class bed and table linen, and to divide it off into marriage portions for their daughters, is nearly, if not quite extinct, a loss which has materially affected the volume of trade. It may be the Lopham weavers, trusting implicitly to their excellent productions to recommend themselves, have not sufficiently advertised their fame to the world. All too few know anything of the industry, though sometimes in the summer visitors will call at the weaving sheds – wealthy and curious London folk, and will ask all manner of questions, promising all the while not to use the information to the detriment of the trade. After watching the shuttles dodging through the myriad threads, they often leave an order, and, departing, will laughingly renew the vow of secrecy – a promise sacredly kept.

All the fabrics are sent away to be bleached, and coming back are finished ready for use, the sewing and marking partly employing the women of the village, the modern sewing machine having no place in the business. Then the orders are taken out, and each parcel is left at the customer’s own door. Through Norfolk, Suffolk, Cambs., Herts, Essex, Surrey, Middlesex, and Kent the delivery vans of Messrs. Beales, T. W. and J. Buckenham and of Mrs Murton, whose business is conducted by her son, John Murton, all these pay their periodical visits to supporters in towns and country common to the manufacturers of both villages, those mentioned by name and others in South Lopham. As the industry exists to-day it deserves the bold advertisement, is worthy of support, and should not disappear for lack of patronage. A native trade deserves a native care.”

(Author unkown)