A post about the two linen looms at Ballydugan Weaver’s House in the Ulster Folk & Transport Museum at Cultra, Northern Ireland. I visited in April 2023 to look at details of loom construction to inform my own loom build later in the year. I am grateful to the weavers Roisin & Joanne for making me so welcome.

.

.

Ballydugan Weaver’s House is a reconstruction of an 1850s weaver’s cottage from Ballydugan, County Down. It currently houses two linen looms, both dating from around 1900. The two looms are similar in size and construction. Both have previously been fitted with Jacquard mechanisms for damask weaving, but one is currently set up for plain weaving with four shafts, with the Jacquard harness removed. in this post I refer to this as the Plain Linen Loom and to the other as the Jacquard Loom.

The Plain Linen Loom

Both looms are fairly typical four-post looms with a post at each corner and open sides, giving easy access for adjusting the harness and dressing the warp. The frame of the ‘Plain Linen Loom’ is 1.5m wide and 1.97m long measured from the outside of the posts, and 1.78 high. The timber appears to be pine. The posts are about 7.5cm wide and 14cm deep. The base of the posts once sat directly on the bare earthen floor but have rotted and now sit on a pair of new floor plates. The treadles are set above a shallow pit in the floor.

The steel warp beam is fitted with a very large brake wheel with sixteen teeth and a large wooden pawl. The ends of the beam are supported on brackets which can be raised or lowered with an iron turnscrew. The warp of bleached linen was wound by Fergusons of Banbridge.

The cloth beam has an iron or steel ratchet with about one hundred teeth. A ratchet mechanism allows the weaver to advance the warp by pulling up on a lever under the seat.

The loom is fitted with a fly-shuttle. The fly-shuttle pickers run on steel rods and are each made from a single block of apple-wood with the grain running across. Small willow branches attached to the swords operate as springs. Old rubber bicycle pedals have been repurposed and fitted on the rods to make buffers to arrest the motion of the pickers.

The batten is hung from a repurposed wooden rail spanning between the tops of the side-frames. The height of the batten can be adjusted by tightening or loosening the twisted cords which secure the swords to the rail.

There are four heddle shafts hung from coupers in the top-castle. The heddles are hand-knitted and varnished. The two treadles are pivoted at the back. There are four lamms or marches pivoted at the left. The front two lamms are tied together, as are the back two. The harness has a counterbalanced action: one treadle raises the two front shafts and sinks the back two, and the other treadle does the oppsoite.

The Jacquard Loom

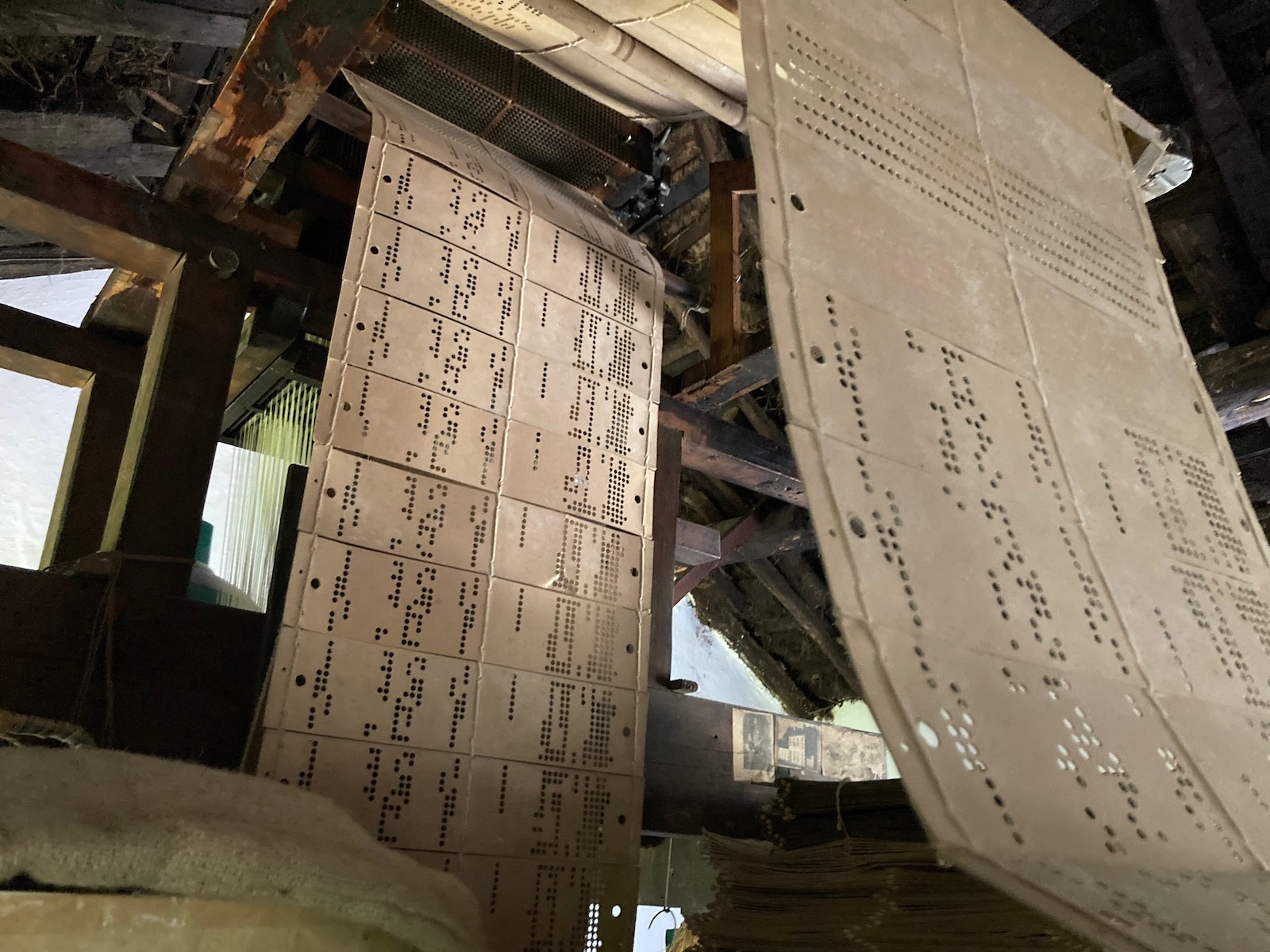

The frame of the Jacquard loom is narrower than the Plain loom but of similar form, with the addition of extra uprights and rails to support the Jacquard mechanism, punch cards and harness.

It has a flanged warp beam with a large wooden brake wheel with only twelve teeth. The pawl lever has an additional step at the end to allow the brake to be held midway between two teeth.

The fly-shuttle arrangement is very similar to that described on the plain loom.

The Jacquard harness works in tandem with the front eight-shaft harness to weave damask.