Building a new loom along historic lines in 2023.

.

.

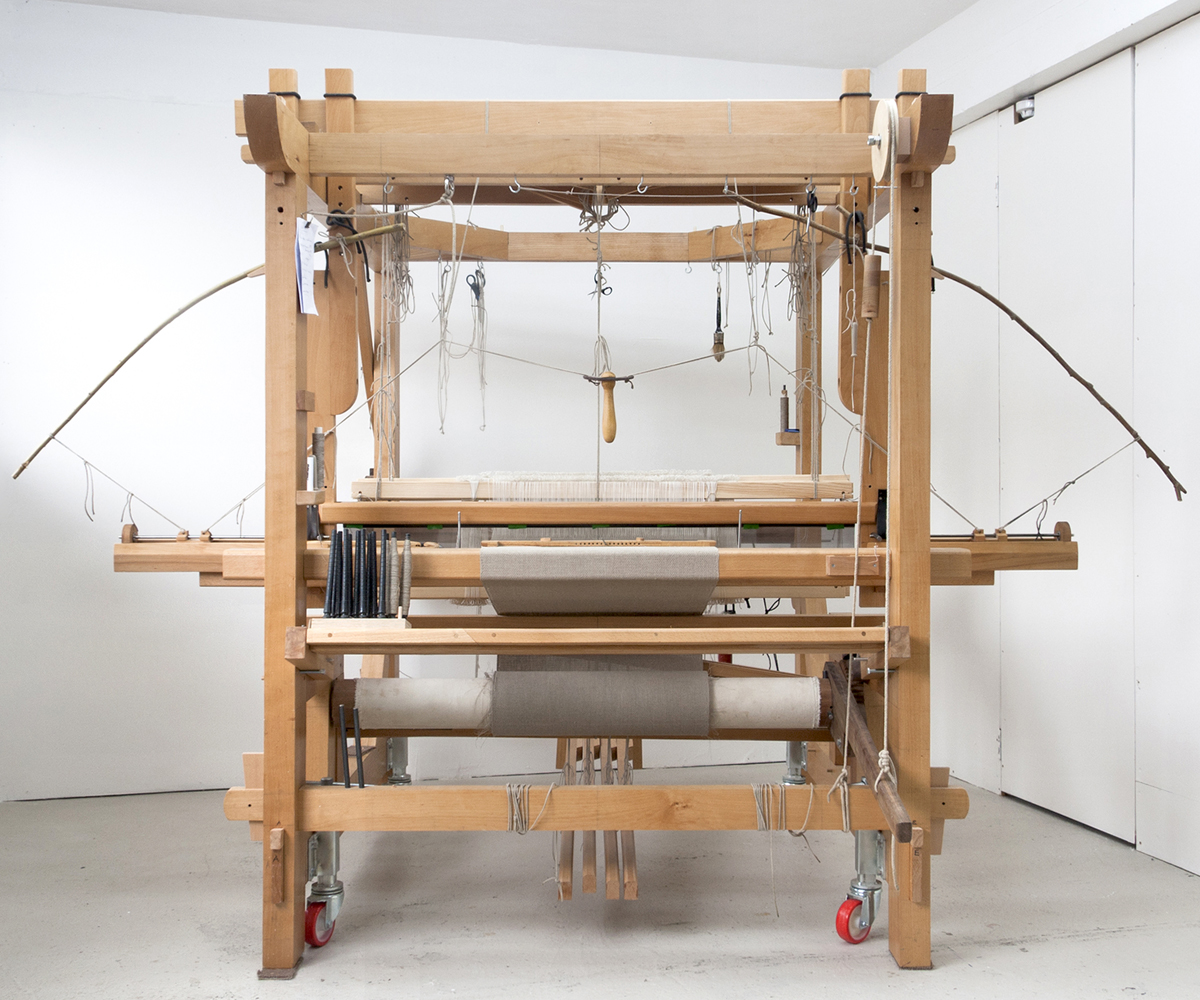

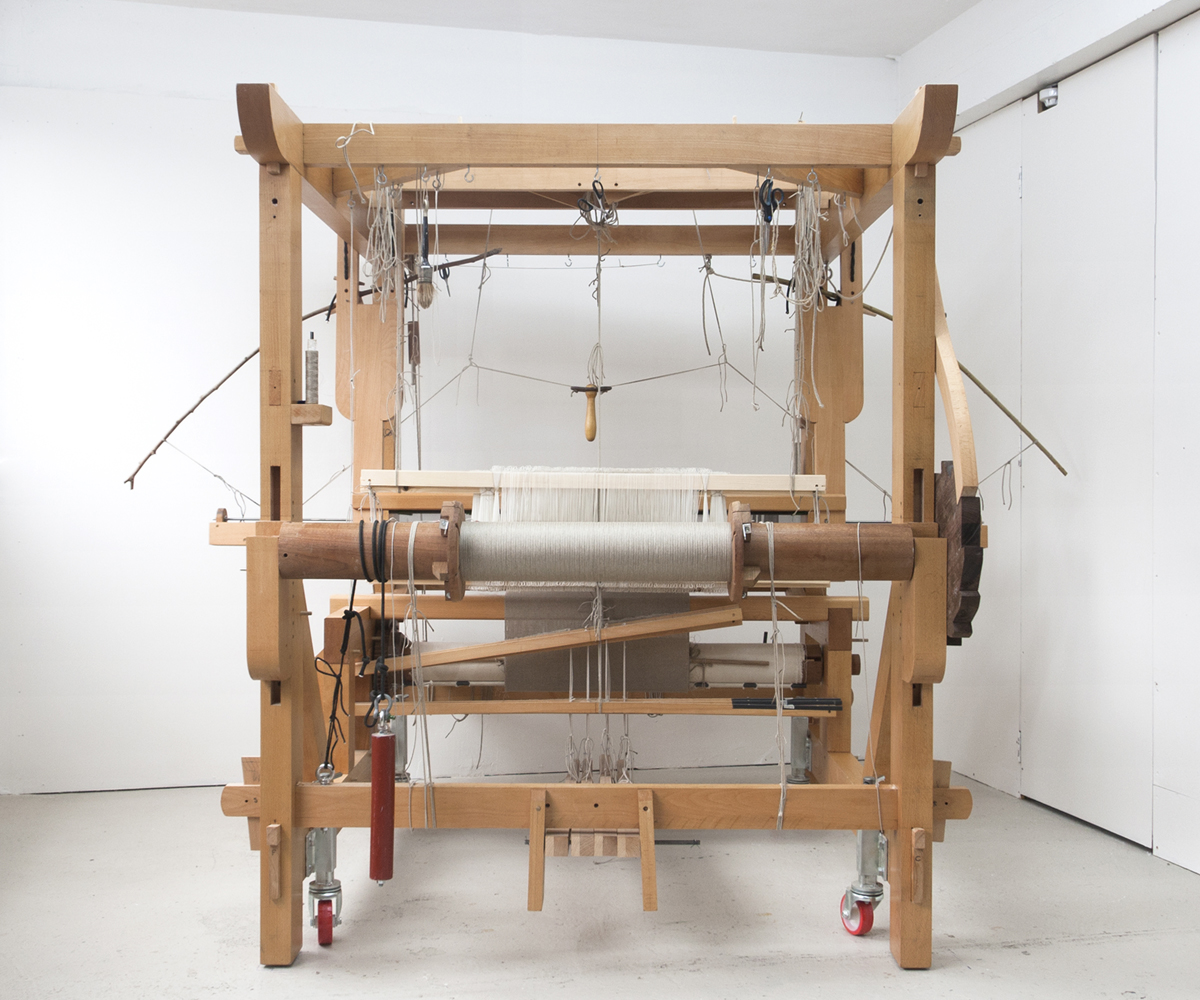

I spent much of 2023 building a new loom specifically for linen. The finished loom is shown in the photographs above. The images further down this post show the various stages of the design and build process.

The loom is modelled on examples of nineteenth century linen looms in museums in England, Scotland and Northern Ireland. These old looms share the ‘four-post’ frame configuration, with a full-height post at each corner, a type sometimes referred to as ‘Old English’ although by no means peculiar to England.1 The framework is strong and heavy to withstand the strenuous beating and high tension needed for closely woven linen. The sides are open, giving easy access to the harness and the warp, and the looms are rather long to expose a generous amount of warp for dressing.2

The new loom has a countermarche shedding mechanism, and is fitted with a fly-shuttle. The unusual forked swords are modelled on those used in North Lopham in Norfolk, adjusted with a twisted cord. The warp beam is fitted with interchangeable ratchet wheels with 12, 14 or 16 teeth. The cloth beam is advanced with a pulley-operated lever and ratchet.

At the very bottom of this post is a video showing how the wedged and pegged joints allow for quick assembly of the loom frame.

.

.

.

.

Notes:

1. See for example my post about the 1724 Treatise known as Farming in Scotland in which the ‘French’ loom has this configuration.

2. The essential characteristics of a good linen loom were described by Percy Beales in the article Hand Loom for Linen Weaving, Quarterly News of the Guild of Weavers Spinners and Dyers, November 1936. Here are some extracts:

If we are intent upon sound work, the essentials towards a good craftsmanship are just as inexorably the same for us as they were for our forefathers. They knew well enough that good linen would never come off a flimsy loom. They built heavily and made all rigid above and below fore and aft…

In order to ensure rigidity, year in year out under constant stress and strain, the old handlooms i knew as a child had their uprights let into and firmly embedded in the ground. When a suspicion of tremor was discovered in the upper framework, this was braced with baulks of timber let into the walls…

The beater must be really heavy and swing forward with considerable force…

An average distance of not less than five feet is a suitable stretch of warp to have exposed at a time.